The 12x12m Aluminum Roof Truss System: A Pinnacle of Contemporary Construction Engineering

In the dynamic realm of construction engineering, technological advancements are continuously propelling the evolution of building systems towards greater efficiency, structural integrity, and sustainability. Among these revolutionary developments, the 12x12m aluminum roof truss system has emerged as a paragon of modern construction innovation, garnering substantial acclaim within the industry.

1. System Overview

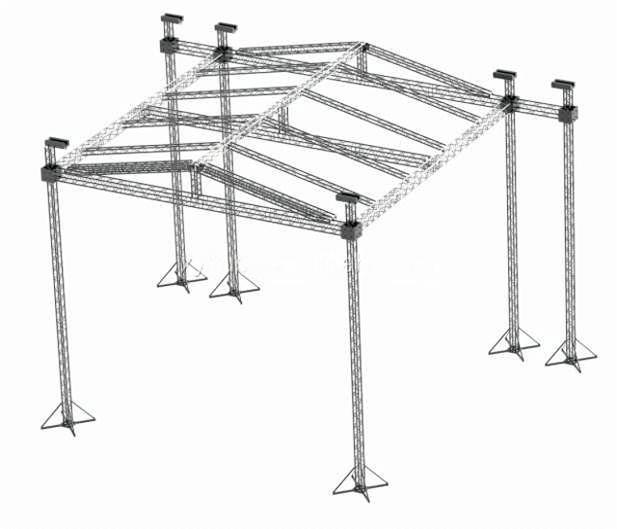

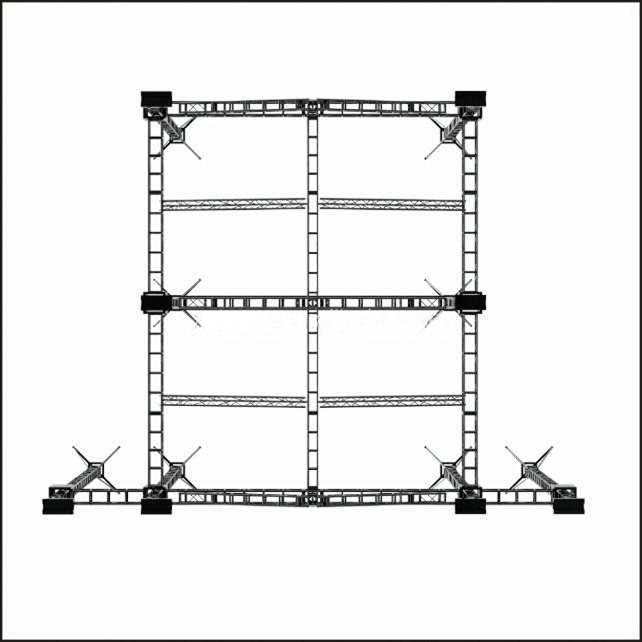

The 12x12m aluminum roof truss system represents a pre - engineered, modular roofing solution fabricated from high - grade aluminum alloys. With a square footprint of 12 meters by 12 meters, it is designed to span large, unobstructed areas, providing architects and engineers with a versatile spatial enclosure option. Aluminum, renowned for its high strength - to - weight ratio, is the material of choice for this system. The trusses are configured in a triangular lattice pattern, a time - tested and mechanically efficient structural arrangement. This geometric design effectively distributes both static and dynamic loads, including dead loads, live loads, and environmental loads such as wind and snow, across the entire structure, thereby ensuring optimal structural performance and long - term durability.

2. Technical Advantages

2.1 Lightweight Construction

Aluminum is approximately one - third the weight of steel, a characteristic that confers significant logistical and installation advantages to the 12x12m roof truss system. The reduced mass eases transportation, requiring less specialized hauling equipment and minimizing associated fuel consumption. During installation, the lightweight nature of the trusses enables the use of smaller, more maneuverable lifting apparatuses, reducing labor intensity and shortening project timelines. This not only cuts down on direct labor costs but also mitigates the risk of construction - related accidents.

2.2 Corrosion Resistance

Aluminum naturally forms a self - protecting oxide layer upon exposure to air, which provides inherent corrosion resistance. This property makes the 12x12m aluminum roof truss system highly suitable for deployment in diverse environmental conditions, particularly in coastal regions with high humidity and salt - laden air, as well as in industrial settings with potential chemical exposure. The low - maintenance requirement of aluminum trusses, in contrast to steel trusses that often necessitate regular painting and rust - prevention treatments, results in substantial long - term cost savings.

2.3 Cost - effectiveness

While the upfront cost of aluminum roof trusses may be higher than some traditional roofing materials, a comprehensive life - cycle cost analysis reveals their long - term economic viability. The reduced installation costs, minimal maintenance expenses, and extended service life, often exceeding 50 years with proper care, contribute to significant cumulative savings over the building's lifespan. Additionally, the thermal properties of aluminum can enhance a building's energy efficiency, reducing heating and cooling loads and associated utility costs.

2.4 Design Flexibility

The 12x12m aluminum roof truss system offers unparalleled design flexibility. It can be easily customized to meet the specific geometric, aesthetic, and functional requirements of various building types. Through the use of computer - aided design (CAD) and advanced manufacturing techniques, the trusses can be fabricated with precision - engineered connections and custom - shaped members, enabling the creation of complex roof profiles, from flat roofs for industrial applications to pitched roofs for residential and commercial buildings.

3. Applications

3.1 Industrial Buildings

In industrial facilities such as factories, warehouses, and distribution centers, the 12x12m aluminum roof truss system offers a practical solution for creating large, column - free interior spaces. The lightweight design allows for the construction of additional stories or the expansion of existing structures without overloading the existing foundation. The corrosion - resistant property is particularly beneficial in industrial environments where exposure to chemicals, moisture, and airborne pollutants is common.

3.2 Agricultural Structures

For agricultural applications, including barns, livestock shelters, and greenhouses, the 12x12m aluminum roof truss system provides a durable and cost - effective roofing option. The large - span capability maximizes the use of interior space, facilitating the efficient storage of agricultural equipment and the housing of livestock. The system's resistance to weathering, including UV radiation, wind, and rain, ensures the long - term protection of agricultural assets.

3.3 Community and Recreational Facilities

In community centers, sports arenas, and event venues, the 12x12m aluminum roof truss system can create a spacious and inviting environment. The design flexibility enables the integration of unique architectural elements, such as skylights, clerestory windows, and decorative truss patterns, enhancing the aesthetic appeal and functionality of the building. The system's ability to support heavy - duty lighting, sound systems, and other equipment required for public events makes it an ideal choice for these applications.